Liquid-coated

• LUXEPOL

Wide range and high versatility

Polyester liquid-cycle pre-coated aluminium laminate manufactured with 3xxx series alloys; being extremely versatile the material is suitable for a number of applications.

• LUXEPOL HD

Super-polyester, super-resistance

Super-polyester (HDPE – High-Density Polyethylene) liquid-cycle pre-coated aluminium laminate. It combines a wide range of colours with the resistance of guaranteed outdoor long-lasting coatings.

• LUXE TX

Structured finishes for a better profiling

Structured polyamide liquid-cycle pre-coated aluminium laminate manufactured with a finish that makes the material particularly resistant to mechanical abrasion and suitable for profiling.

• LUXEPLUS

We value details

PVDF liquid-cycle pre-coated aluminium laminate up to 1.5 mm of thickness. It is intended for architectural applications, for the manufacturing of accessories and for door/window flashing. The homogeneity of the finish and the facade panels is guaranteed.

• LUXEPLUS 2.3

Product for facades up to 2-3 mm thick. Incombustible, class A1

3xxx alloy for a better resistance to corrosion, incombustible, class A1. PVDF liquid-cycle pre-coated aluminium laminate up to 2-3 mm of thickness, intended for the manufacturing of metal coatings and facades.

• LUXEWALL 2.3

Ultra-high performance 5xxx-alloy product for facades, incombustible, class A1

PVDF liquid-cycle pre-coated aluminium laminate up to 2-3 mm of thickness. Thanks to the use of 5xxx Mg series aluminium alloys and 2/3/4-layer PVDF coating cycles, the product is particularly suited for applications in the architectural sector, which requires resistance and long-lastingness.

• LUXESIGN

Aluminium for design and communication

Aluminium laminate pre-coated in liquid mode with polyurethane cycles specifically designed for screen printing and digital printing. It is available in a wide range of colours and levels of brightness.

• ANTI-GRAFFITI LUXESIGN

No graffiti, clean facades.

Pre-coated aluminium laminate with a coating cycle that is specifically designed to enable the removal of wall graffiti with neutral solvents. Available in a wide range of colours finishes and levels of brightness.

Powder

• LUXE POWDER

The only Italian aluminium laminate produced with continuous powder-coating from 0.8 to 3mm

Thanks to the thicker paint film, the product offers better protection and very easy processing, perfect homogeneity of the finishes of the coated extruded profiles. Suitable for facades, construction accessories, doors and windows, billboarding and in general for press brake bending products.

Anodized

• C-ICONIC

“Zero tolerance” for a perfect color on large surfaces!

Pre-anodized aluminium laminates for architectural projects made paying specific attention to the homogeneity of the finishes through an accurate selection of the aluminium support and the use of higher manufacturing standards.

• C-WALL

Wide range and high versatility

Pre-anodized aluminium laminate with natural and coloured finishes for a wide variety of applications.

• C-BRITE

For a product with contemporary reflections

Anodized aluminium on a support with a gloss finish that creates a semi-reflecting effect similar to the satin finishes of steel. Decorative sector and facade coatings. Full colour range available.

• C-BRUSH

For a product with “steel-effect” finishes

Anodized aluminium on a support with brushed finish that creates a deep satin effect suitable for a wide variety of sectors. Full colour range available.

• C-THRU

From the classic applications in the highway barrier sectors to the new architectural frontiers

Pre-drilled aluminium anodized in continuous mode that guarantees colour evenness and homogeneity and full protection to the anodic coating on the whole surface and inside the hole.

• C-BOND

Suitable for all types of bonding. Corrosion-resistant surface also with gloss and brushed finish

The product is specifically designed for the production of composite panels. It combines a highly accurate cleaning of the back-bonding surface with an anodisation process that guarantees corrosion resistance and colour stability on the front, also for lower anodisation degrees of thickness (0.3 – 0.5 mm).

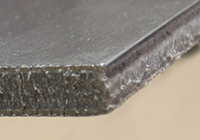

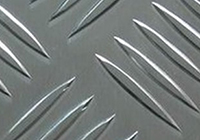

• C-TREAD

Anodized aluminium diamond plate with natural and/or coloured finishes

The product assures perfect and even covering of the processed surface, combining the wide range of colours available and adapting a typically industrial product to new decorative applications.

• C-DECO

Designer-proof

Anodized aluminium laminate with finishes that assure maximum evenness for design and interior design applications (metal luggages, furniture and kitchens).

• C-TECH

Ready to be transformed

The laminates are pre-anodized in continuous mode. The anodic bath makes the surface particularly reactive and therefore suited for subsequent processing, e.g. bonding, coating and welding.

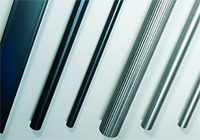

• C-FLEX

Ideal product for corrugated sheets

Aluminium laminates anodized in continuous mode with a process that enables bending and profiling without affecting the features of the anodisation layer.

In particular, the continuous anodisation process ensures colour stability over time.